The 1994 Formula 1 season marked a significant shift in the sport's technical landscape. New regulations banned a host of driver aids, including traction control, active suspension, and launch control.

These changes aimed to place more emphasis on driver skill and reduce the perception that cars were becoming "too easy" to drive. Among the teams grappling with these new rules, Benetton emerged with an innovative approach to traction control that would prove both controversial and highly effective.

Prior to 1994, traction control had become an integral part of Formula 1 technology. These systems monitored wheel spin and automatically adjusted engine power to maintain optimal traction.

While effective, they were seen by many as diminishing the role of driver skill. The FIA, Formula 1's governing body, decided to ban such systems to re-emphasise the human element in the sport and potentially level the playing field between teams with varying budgets.

The ban on traction control presented teams with a significant technical challenge. Suddenly, drivers had to manage wheel spin manually, particularly during starts and exits from low-speed corners. This not only affected lap times but also tyre wear and therefore overall race strategy.

Teams that could find ways to assist their drivers in managing traction, without violating the new regulations, stood to gain a substantial competitive advantage.

Benetton's Solution

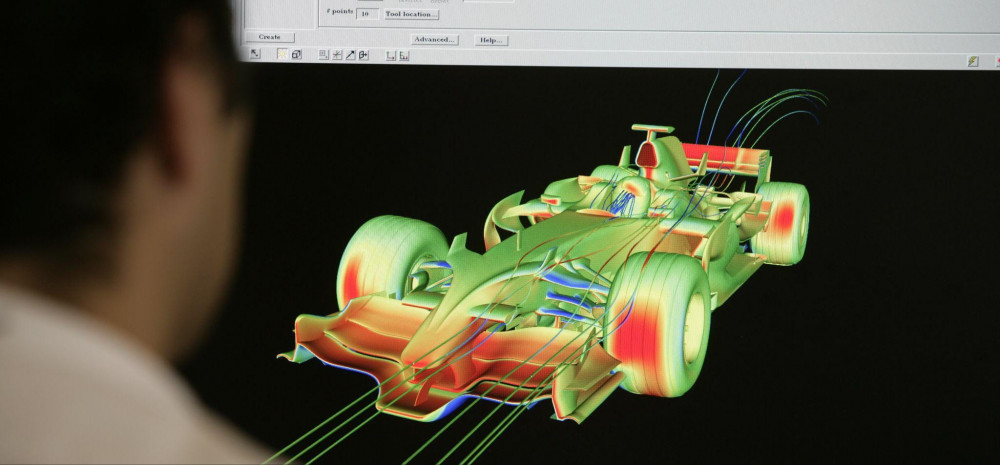

Benetton's approach centred around a clever interpretation of the rules regarding engine management systems. At its core, their solution used the car's air intake pressure sensor, a component typically used for adjusting engine mixture and timing based on atmospheric conditions.

By repurposing the data from this sensor, Benetton created a proxy for vehicle speed and gear selection, allowing them to implement a form of traction control without directly violating the regulations.

Technical Deep Dive

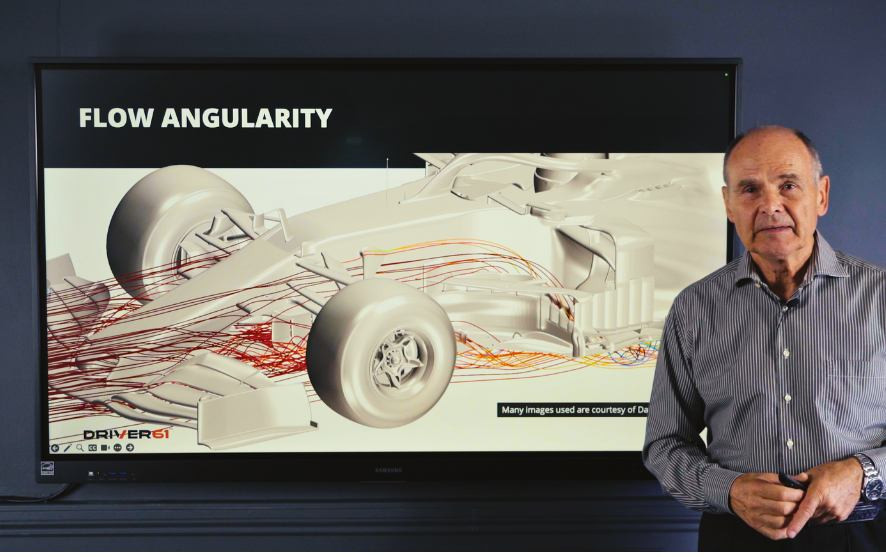

The ingenuity of Benetton's system lay in its exploitation of a fundamental principle of fluid dynamics: the ram-air effect. As an F1 car accelerates, air is forced into the engine intake at increasing pressure. This pressure increase is directly related to the car's speed.

Here's how the system functioned:

1. Baseline Measurement: At the start of each race, the system would measure the ambient atmospheric pressure. This served as a reference point.

2. Dynamic Pressure Monitoring: As the car accelerated, the air intake pressure sensor would detect increases in pressure due to the ram air effect.

3. Speed and Gear Estimation: By analyzing the rate and magnitude of pressure changes, the ECU could estimate the car's speed and current gear. This was possible because each gear would have a characteristic pressure profile as the car accelerated through it.

4. Acceleration Limiting: Based on these estimates, the ECU would limit the engine's acceleration rate. This limiting was tailored to each gear and could be adjusted for different tracks and conditions.

5. Continuous Adjustment: The system would continuously monitor pressure changes, allowing it to adapt as the car moved through different gears and speeds.

The physics behind this system are relatively straightforward. The ram air effect follows the Bernoulli principle, where an increase in the speed of a fluid occurs simultaneously with a decrease in static pressure or a decrease in the fluid's potential energy.

In the case of an F1 car, as it accelerates, the air entering the intake experiences an increase in dynamic pressure. This increase is proportional to the square of the car's velocity, providing a reliable indicator of speed.

Implementation and Refinement

Initially, Benetton implemented this system primarily for first-gear starts, where traction control would be most beneficial. As they refined the system, they expanded its operation to cover second and third gears as well. This expansion required careful calibration, as the pressure profiles for each gear would be distinct.

The team had to develop complex algorithms to interpret the pressure data accurately. These algorithms needed to account for various factors, including atmospheric conditions, track layout, and even tyre compound. As the season progressed, Benetton continually refined these algorithms, improving the system's accuracy and effectiveness.

Advantages and Limitations

Benetton's system provided several key advantages. It offered improved traction out of low-speed corners and during starts, reducing wheel spin and potentially improving tyre life. The system also allowed for more aggressive throttle application, potentially improving lap times.

However, it was not without limitations. Unlike true traction control systems, which could dynamically adjust based on real-time wheel spin data, Benetton's system was essentially predictive. It was most effective when tyres were in optimal condition and became less so as tyres degraded. Additionally, it required careful setup for each track and couldn't adapt to changing conditions as effectively as a true traction control system.

Regulatory Grey Area

The brilliance of Benetton's approach lay in how it navigated the regulatory landscape. The system didn't use any explicitly banned sensors or systems. Instead, it repurposed allowed engine management parameters in a novel way. This made it difficult for regulators to definitively declare the system illegal, as it didn't directly violate any specific rule.

Detection and Concealment

Despite its clever design, the system didn't go unnoticed by competitors. Other teams, particularly through astute drivers like Ayrton Senna, became suspicious of the sound of the Benetton cars, which at times resembled the characteristic stuttering of traction control systems.

Benetton went to great lengths to keep the exact workings of their system secret. They were careful in their communications, both internal and external, and were selective about which team members had full knowledge of the system. When scrutineered, the team was prepared with plausible explanations for any questionable aspects of their engine management software.

Legacy and Impact

Benetton's innovative approach to engine management in 1994 stands as a prime example of the ingenuity often found in Formula 1. It demonstrates how teams operate in the grey areas of regulations, seeking every possible advantage while avoiding outright rule violations.

This system, and others like it, led to increased scrutiny of engine management software in subsequent years. The FIA began to require teams to submit their software for approval, and regulations became more specific about what was and wasn't allowed in terms of driver aids.

More broadly, this episode highlights the constant cat-and-mouse game between regulators and teams in Formula 1. As rules are written to close off one avenue of development, teams invariably find new ways to push the boundaries, driving innovation in unexpected directions.

Benetton's engine management system from the 1994 season represents an example of an F1 engineer's ability to read and interpret the regulations, something we know Adrian Newey is a master of.

By repurposing existing sensors and exploiting fundamental principles of physics, the team created a system that provided many of the benefits of traction control without explicitly violating the regulations.