At Cosworth, piston engineering represents the pinnacle of precision manufacturing.

In today's article, we're going to delve into the engineering processes, cutting-edge tooling, and of course, the expertise required to produce pistons for high-performance engines, from Formula 1 to hypercars like the astonishing Aston Martin Valkyrie.

How Formula 1 Pistons Are Made - DRIVER61

Design Phase

The journey of a Cosworth piston begins in the design department. Cosworth engineers, typically holding advanced degrees in mechanical engineering and/or materials science, use state-of-the-art CAD software such as Siemens NX for initial modelling.

The design process, which can take 4-8 weeks, involves:

- Defining engine architecture: bore, stroke, and valve positioning.

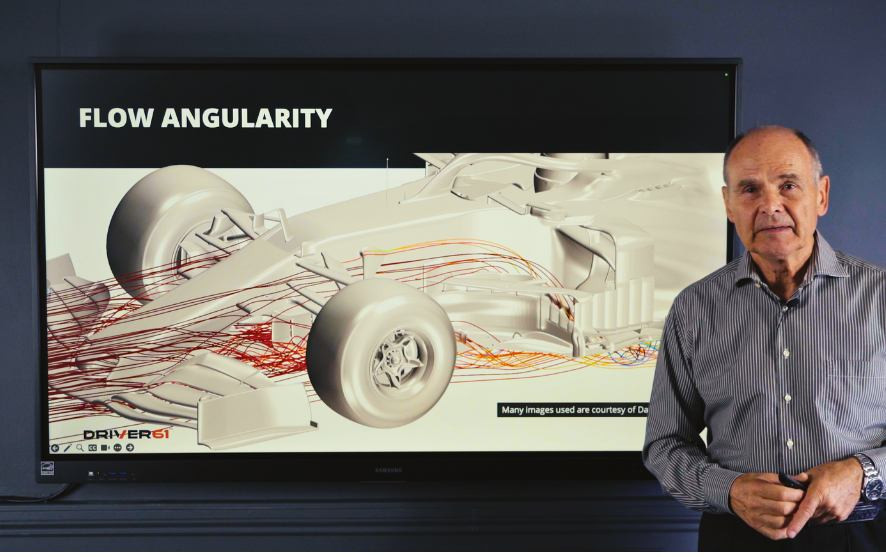

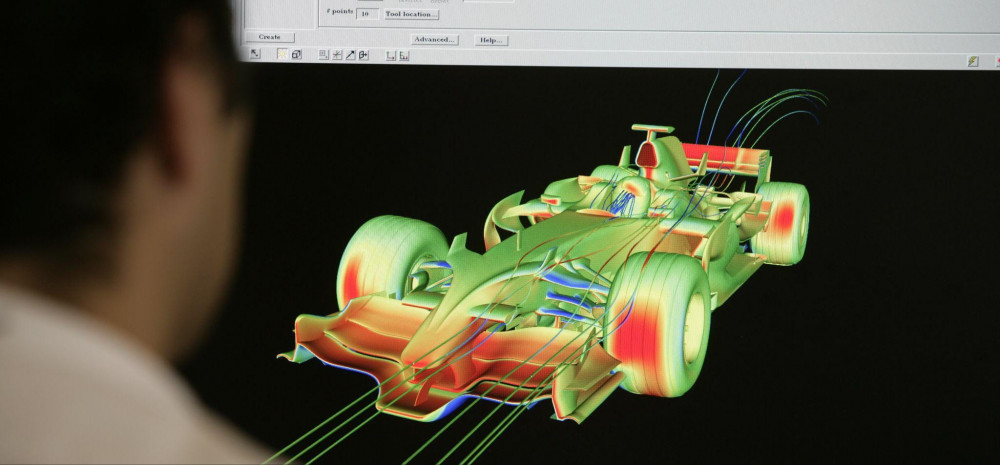

- Crown design: Engineers use CFD (Computational Fluid Dynamics) to optimise combustion chamber shape for efficient fuel burning and reduced knock.

- Structural analysis: FEA (Finite Element Analysis) is employed to model stress distribution and optimise the piston's structure for strength and weight.

FEA image of a piston

The key skills at play in the design process (which are usually at a minimum of MSc level are proficiency in CAD software, a thorough understanding of thermodynamics, materials science, and structural mechanics.

Material Selection and Engineering

Cosworth pistons use advanced aluminium alloys, chosen for their strength-to-weight ratio and thermal properties.

Aston Martin Valkyrie Engine (Cosworth)

For projects like the Valkyrie engine, where pistons must withstand peak combustion pressures of 140 bar at over 11,000 rpm, material selection is critical.

Cosworth materials engineers work on:

- Alloy composition optimisation

- Heat treatment processes

- Surface treatments and coatings (e.g., thermal barrier coatings, wear-resistant skirt coatings)

The key skills at play in this phase: Metallurgy, thermal engineering, surface engineering.

Manufacturing Process

Piston production at Cosworth combines cutting-edge technology with traditional craftsmanship:

- Forging: Using high-pressure forging machines, they shape heated aluminium billets (400-500°C) into rough piston forms. This process aligns the metal's grain structure for optimal strength.

- CNC Machining: Cosworth employs 5-axis CNC machines like the DMG DMU50 for precision machining. These 7.5-tonne machines can achieve tolerances down to a few microns.

- Precision Turning: High-precision lathes like the Takisawa are used for final dimensioning. These machines can create the slightly oval shape required for optimal piston performance under operating conditions.

Key skills at play: CNC programming, understanding of metalworking processes, metrology.

Quality Control

The Cosworth QC process involves

- CMM (Coordinate Measuring Machine) inspection for dimensional accuracy.

- Non-destructive testing, including penetrant testing for micro-cracks.

- Surface finish analysis.

Key skills: Metrology, understanding of non-destructive testing methods, statistical process control.

Testing and Validation

Final piston designs undergo rigorous testing:

- Single-cylinder engine tests for combustion analysis.

- Full engine dynamometer testing, simulating race conditions (e.g., extended Monza circuit simulations for F1 engines).

Key skills: Data acquisition and analysis, engine calibration, understanding of tribology.

Software and Tools

Throughout the process, our engineers use a range of specialized software:

- CAD: Siemens NX

- FEA: ANSYS or Abaqus

- CFD: STAR-CCM+ or ANSYS Fluent

- Data Analysis: MATLAB, Python

- Project Management: Agile methodologies, often using tools like JIRA

Continuous Learning: Cosworth emphasizes continuous learning. Their engineers regularly attend conferences, participate in research projects with universities, and engage in internal knowledge-sharing sessions.

Piston Engineering at Cosworth represents a blend of advanced technology, materials science, and precision manufacturing.

For engineers passionate about pushing the boundaries of performance, it offers a challenging and rewarding career path. From CAD to dyno, every step in the process demands excellence, innovation, and an unwavering commitment to engineering precision.