Featured Image: Fibreworkscomposites.com

For those dreaming of a career at the cutting edge of motorsport technology, Tim Anway's journey offers a useful roadmap. As Engineering Director at Fiberworks, a company specialising in composite component development, design and production in Formula 1, NASCAR, and IndyCar.

I had a highly engaging discussion with Tim, and, if you’re interested in the future of materials science or you’re interested in a career in composite engineering, our latest podcast is for you:

Listen on Spotify or Apple Podcasts, or, watch the video below.

How to Get a Job in Carbon Composites - FluidJobs on YouTube

If you’re keen to dig a little deeper into the subject, let’s take a quick look at the historical development of composites in F1 (naturally, as F1 pioneered the carbon tub in the 1980’s).

Composites in Motorsport: a Brief History

Lotus 72 (image credit)

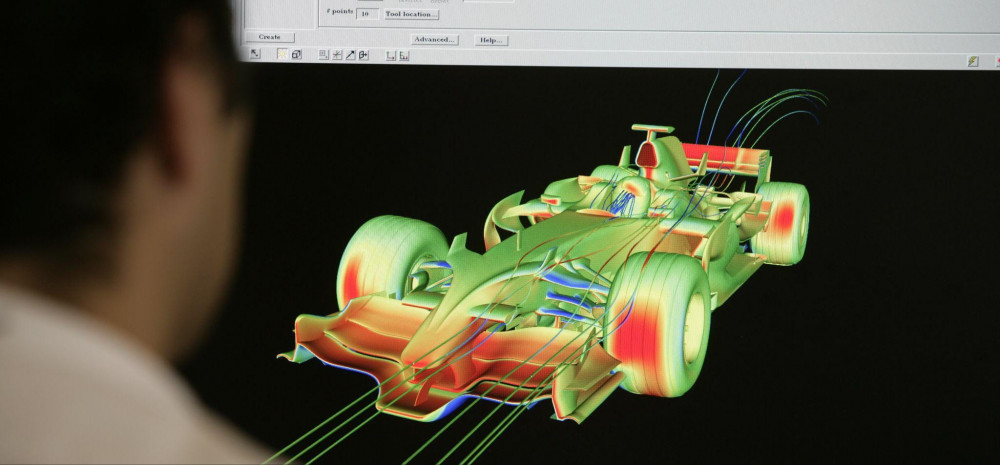

In the 1960s and 1970s, teams began experimenting with glass-reinforced plastic (GRP) for non-structural bodywork, allowing engineers to design rudimentary aerodynamic shapes without adding significant weight to the overall package. These pioneering designs turned the cars into “upside down wings” which, of course, led to greater cornering speeds, growing safety concerns and eventually, tougher regulations on the car designs.

But the real revolution came in 1981 with McLaren's MP4/1. This F1 car was built on the world’s first full carbon fibre reinforced polymer (CFRP) chassis in grand prix racing.

Mclaren MP4/1b

At the time, it was difficult for some engineers to believe the tub wouldn’t turn into dust in case of impact.

Little was known about the material in Motorsport. This breakthrough, which was inspired by cutting-edge aerospace manufacturing techniques, offered an immediate advantage in the stiffness and overall potential for safety improvements.

Throughout the 1980s and 1990s, CFRP (carbon fibre-reinforced polymer) rapidly became the standard across the grid, with teams refining manufacturing techniques and expanding its use to various components.

The 2000s saw composites applied to increasingly complex structural elements, including CFRP gearbox casings and more and more advanced aerodynamic parts. Continuous improvements in energy-absorbing structures also enhanced driver safety over time, with crash test requirements first being introduced in 1985.

Mercedes W07 Hybrid gearbox and rear suspension assembly - Credit: automotorundsport

Today, modern F1 car builds comprise of approximately 85% composite materials by volume while accounting for less than 25% of the vehicle's mass. This extensive use extends beyond the primary structure to include suspension elements, brake ducts, and cooling systems, showcasing the material's versatility and importance in cutting-edge motorsport engineering.

Back to the Composite Career Journey

Tim Anway's path to the top of the composite engineering world wasn't quite straightforward. His passion for speed began with motorcycles and participating at track days. He studied engineering at the University of Washington, and, after a transfer to UNC Charlotte and subsequent involvement with Formula Student (known as Formula SAE in the US), his career in Motorsport was set in motion.

F1 Stockcar with carbon work by Fiberworks (image credit)

Through the connections he made in the program, Anway secured his first job at Michael Waltrip Racing, a NASCAR team. From there, he joined Fiberworks, initially focusing on CATIA software implementation before working his way up to his current role overseeing a team of about 20 engineers.

Anway's career progression highlights a crucial point for aspiring engineers: the value of practical experience and networking. While a strong academic foundation is essential, hands-on project work and industry connections can be the difference-makers in landing that first crucial role.

Autoclave at Fiberworks

What Skills are Required for a Successful Career in Composite Engineering?

According to Anway, a solid grounding in engineering basics like statics, dynamics, and thermodynamics is non-negotiable.

Proficiency in CAD software, particularly CATIA, is highly prized in the motorsport industry whatever your specialism.

Perhaps most importantly, a deep understanding of modern composite materials and manufacturing processes is crucial, as is the ability to work in a Motorsport based environment, which we know, can be fast paced and stressful at times.

Interestingly, Anway notes that composites are often under-taught in universities, especially in the US. This gap in formal education makes internships and hands-on projects even more valuable for aspiring composite engineers.

The field is in constant flux, with new materials and manufacturing techniques continuously being developed, so learning on the job comes in the job description.

Break into the Industry

For those looking to break into the industry, Anway's advice is clear: seek out educational programs that offer specialised classes in composites and carbon fibre, get involved in Formula Student or similar projects, pursue internships, and develop a strong technical foundation. Be prepared for a dynamic work environment where rapid growth and technological changes are the norm.

The world of composite engineering in motorsport offers a variety of career paths. Design engineers at Fiberworks, for instance, wear many hats, handling not just design work but also project management, quality control, and customer service.

Facility equipment at Fiberworks

R&D engineers focus on pushing the boundaries with new technologies and materials, while manufacturing engineers work on optimising production processes and maintaining quality standards.

Tim Anway's journey from a motorcycle enthusiast to a leader in composite engineering illustrates the exciting possibilities in this field.

For those with a passion for engineering and racing, a career in composite engineering offers the chance to work at the forefront of materials technology, with constant innovation while pushing the limits of what's possible.

With the right combination of technical skills, practical experience, and industry connections, you too could find yourself crafting the future of motorsport, one composite part at a time.

Further Reading / Resources:

https://www.fibreworkscomposites.com/about-us/

https://www.compositesworld.com/articles/class-a-composites-a-history