Image credit: motorsport.tech

Are you a hydraulics specialist who values precision and performance?

Consider applying your expertise to motorsport's leading edge, where literally every millisecond matters. Formula 1 relies heavily on advanced hydraulic systems alongside engines and aerodynamics.

For hydraulic fitters, specialists or engineers seeking a career-defining challenge, F1 teams are actively looking for your skills.

The Hidden Force: Hydraulics in F1

F1 cars operate at engineering extremes, requiring high power levels and responsiveness in a compact lightweight package.

This is where hydraulics excels. Compared to electric or pneumatic alternatives, hydraulic systems deliver superior power density, making it an ideal solution for critical F1 car functions.

Consider that drivers must manage tremendous forces at high speeds, gear changes must be instantaneous yet precise, and various systems continuously optimise the car's balance and performance. Hydraulics controls much of this functionality.

Key hydraulic systems in Formula 1 include:

- Power Steering: Helps drivers handle extreme steering forces while maintaining essential feedback.

- Gearshift: Enables near-instantaneous gear changes to maximise acceleration and performance.

- Clutch: Controls power delivery from race starts to smooth gear changes.

- Differential: Manages torque distribution between wheels for optimal traction and cornering.

- Reverse Gear: Though rarely used during races, essential for manoeuvring in garages and pit lanes.

- DRS (Drag Reduction System): Precisely adjusts rear wing angle to reduce drag during overtaking opportunities.

- Brake-by-Wire: Controls rear brake pressure and integrates with regenerative braking in hybrid cars.

- Throttle Control: Provides precise modulation of engine power output.

- Engine Valve Control & Turbo Wastegate: Used in some engine designs to optimise performance and responsiveness.

Historically, F1 has also employed hydraulics for active suspension, rear-wheel steering and fuel flap actuation, demonstrating the versatility of hydraulic technology in this demanding environment.

Skills for Success as an F1 Hydraulics Engineer

What specific abilities will help you excel in Formula 1? Beyond basic hydraulics knowledge, you'll need to apply your expertise in an environment that demands exceptional performance, reliability and innovation.

F1 teams value these skills in hydraulics engineers:

Deep Understanding of Hydraulic Principles

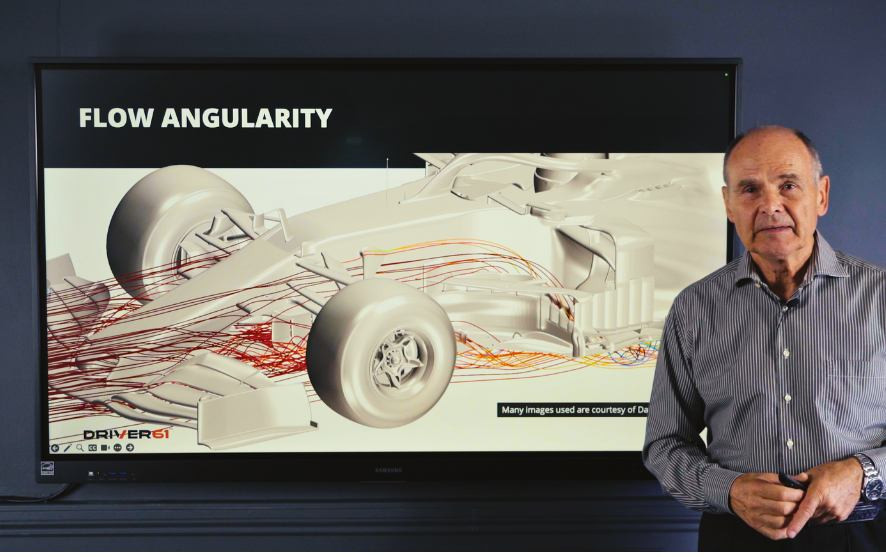

This forms your foundation. F1 requires comprehensive knowledge of fluid dynamics, pressure control, flow rates and system design. You'll need to understand theoretical concepts to push engineering boundaries.

F1 Application: Designing systems that function under extreme conditions – high pressures, rapid accelerations and intense heat – demands a profound understanding of these principles.

Expertise in Hydraulic Components

Familiarity with various hydraulic elements is essential, including:

- High-pressure pumps (particularly swash plate designs)

- Precision servo-valves for fast response

- Accumulators (HPAs & LPAs) for pressure regulation

- Linear and rotary actuators

- Complex valve blocks and manifolds

- Heat exchangers and cooling systems

- Hydraulic fluid selection and management

F1 Application: Formula 1 uses specialised versions of these components that often push technological limits. Your expertise in selecting and potentially innovating these components is valuable.

(F1 Hydraulic Control: Ferrari)

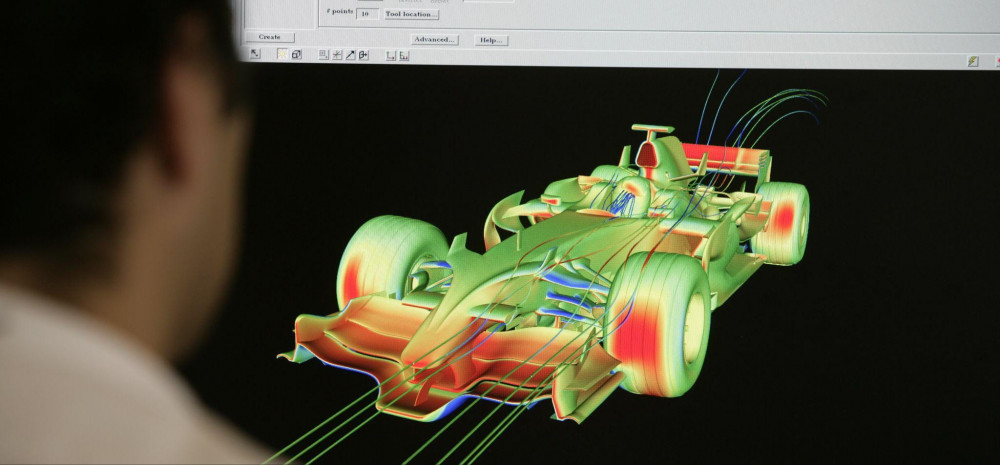

System Design and Integration

Understanding components isn't sufficient; you must design complete hydraulic systems:

- Circuit design and analysis

- Compact packaging and integration

- Advanced materials selection

F1 Application: Space is extremely limited in F1 cars. Hydraulic systems must be compact and lightweight while delivering maximum performance and reliability.

Problem-Solving and Diagnostics

F1 is fast-paced and demands quick solutions:

- Efficient fault finding and diagnosis

- Thorough root cause analysis

- Data analysis and interpretation

F1 Application: Races can be decided by reliability. Your ability to quickly diagnose and resolve hydraulic issues could determine race outcomes.

Precision and Attention to Detail

F1 tolerances are exceptionally tight:

- High-tolerance manufacturing knowledge

- Rigorous cleanliness and contamination control

F1 Application: Formula 1 operates at the leading edge of precision engineering. Your meticulousness will be crucial.

Adaptability and Performance Under Pressure

The F1 environment is intense and dynamic:

- Working to strict deadlines

- Effective teamwork and communication

- Potential trackside support

F1 Application: The race calendar dictates everything. Adapting to changing situations, working under pressure and being a team player are essential.

Hydrualics Specialist? Your F1 Adventure Awaits

For hydraulics engineers looking to push technological boundaries, Formula 1 offers an unmatched opportunity. Your understanding of fluid power becomes vital, directly contributing to a racing machine's performance at its absolute limit.

Beyond applying existing skills, F1 requires constant innovation and problem-solving under pressure, with the satisfaction of seeing your engineering expertise translate to results on the world stage.

If you're ready to advance your hydraulics career and embrace an extraordinary challenge, Formula 1 awaits. Explore the opportunities and discover how your fluid power expertise can drive success in motorsport's most exhilarating discipline.